Failure to follow these warnings may result In serious bodily Injury or death.

Read and understand all warnings. The purchaser/user should be knowledgeable and familiar with the use, care and Inspection of our products. Use and design Is the responsibility of the user.

Working load limits are based on a straight vertical lift In a gradually Increasing manner. Any deviations such as angular lifts, shock loads, modification of the basic part, etc., will result In drastically reduced maximum loads.

Always Inspect items for visible damage, rust, fatigue corrosion, etc. before each use.

Make sure items in assemblies match.

Never exceed working load limits even when product is new.

Never use an item for a purpose it is not intended.

Never ride on a load.

Always keep from under a raised load and away from the line of force.

Never use an item if you are uncertain of its strength or working load limit.

Never misuse, overuse or abuse products.

Do not shock or side load. If this occurs, remove affected item from service immediately.

Always consult and understand applicable OSHA, ANSI, CVSA or relevant industry standards before using any item in this catalog

Frequent Inspection and maintenance are the responsibility of the user and must be done without exception.

Always use items in compliance with relevant codes and wear appropriate safety equipment.

In each section of this catalog, there are printed warnings specific to products in that category. Please become familiar with these warnings and cautions and always comply with all regulations, applicable codes and industry standards.

Ultimate responsibility for correct use lies with the end user.

Breaking strengths are for reference use only. They are calculated under controlled test conditions.

Chain Warnings

Never exceed the Working Load Limit (WLL) of the chain.

Only grade 80 alloy chain or higher should be used for over head lifting.

Remember to always match components.

Avoid shock loads.

Assemblies will carry the WLL of the weakest part.

Never move a load over people.

Frequently inspect chain. Never use chain that has a deformed link, rust, crack or any indication that would cause doubt about its strength.

Always destroy defective chain by cutting it into short pieces, to prevent someone from using it.

Refer to OSHA standard 1910.184 and ASME standard B 30.9 for current design factors for chain slings.

Fittings and Snatch Block Warnings

Always inspect fittings before each use.

Never use damaged, cracked, rusted or worn items.

Always inspect snatch blocks for lubrication and condition prior to use.

Refer to OSHA Rule 1926.550(g) and OSHA CPL 2-1.29. for specific information regarding hoisting and using snatch blocks.

Remove from service any snatch block that is cracked, rusted or deformed.

Never lift any person using a snatch block.

Always apply load in a gradually increasing manner. Angular lifts dramatically reduce capacity. Avoid shock loads. Do not replace pins or bolts or modify or weld.

OSHA requires that all harnesses and lanyards damaged by burns or heat must be immediately replaced. Our Series FPHOT Welders hardnesses are constructed from heat resistant Kevlar™ webbing and come standard with back and side “D” rings. Coupled with our Kevlar™ lanyards, you can reduce your replacement costs and minimize your risk.

Rereeling Wire Rope

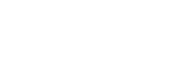

When reeling rope from one reel to another, it is preferable for the wire rope to travel from top to top, as illustrated.

Spooling from bottom to bottom is also acceptable, provided the surface over which the wire rope will travel is clean, smooth and dry, so as not to allow foreign particles to become embedded in the wire rope. Spooling from top to bottom or from bottom to top can put a reverse bend into wire rope.

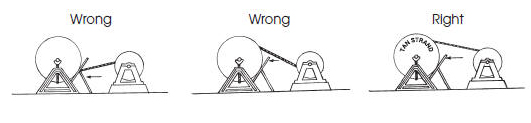

Unreeling or Uncoiling Wire Rope

Great care must be taken when removing wire from reels or coils. Looping the rope over the flange of the reel or pulling the rope from coil while it is lying on the ground will create loops in the line. If these loops are pulled tight, kinks will result, thereby permanently damaging the wire rope. Check illustrations below showing correct and incorrect ways of unreeling and uncoiling wire rope.

Whenever handling wire rope, take care not to drop reels or coils. This can damage wire rope and collapse the reel, making removal of the wire rope extremely difficult if not impossible.

Wire Rope and Aircraft Cable Warnings

It is the user’s responsibility to know and understand the proper care and maintenance of these products. Always refer to the Wire Rope Users Manual by the Wire Rope Technical Board, available by calling 1-888-289-9783.

Avoid shock loads and side loads.

Always inspect prior to use (by a qualified person familiar with wire rope).

Remove from service immediately if damaged, broken, rust, lack of lubrication (wire rope) or any apparent abnormal condition is visible. Proper use, care and inspection of the product and the system or application in which it is used is imperative.

Keep out of the line of force of any load.

Never operate a load over people.

Make sure to match components and reduce accordingly for specific termination types. Choose the correct wire rope/aircraft cable and keep within its rated capacity.

Ultimate responsibility for applications and design rests with the end user and the original equipment manufacturer.